Chromatography cabinet principles, applications, and main hardware performance indicators

Release Date:

2025-05-16 14:58

I. Chromatography Cabinet

The chromatography cabinet is a special-purpose low-temperature cabinet developed specifically for biochemical chromatography experiments. It can also be used for other experiments requiring a low-temperature environment, or for storing items in cold storage. Through scientific design, the total height of the refrigerator generally does not exceed 2 meters, making it easy to enter and exit rooms and elevators.

II. Uses of Chromatography Cabinets

Primarily used in university disciplines and research institutes for life science research, mainly for biochemical chromatography analysis experiments of various enzymes, peptides, macromolecules, nucleic acids and other substances. It can also be used for other experiments requiring a low-temperature environment, or for cold storage of items. Specifically designed for various applications with high temperature requirements, chromatography equipment and other easily installed instruments and devices can be operated inside the cabinet.

III. Hardware Composition of Chromatography Cabinets

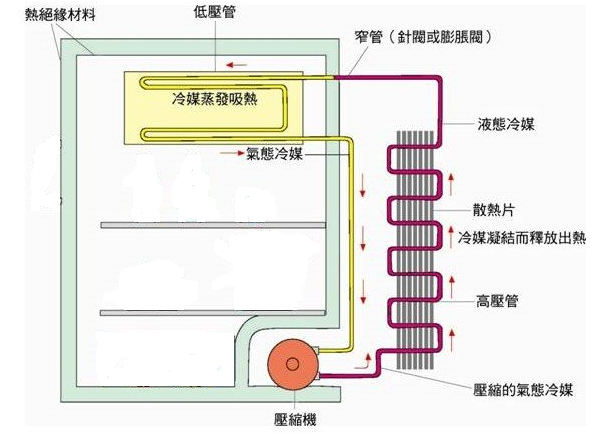

1. Refrigeration System

A standard refrigeration system consists of a compressor, condenser, evaporator, expansion valve, solenoid valve, etc.

These devices are connected sequentially by pipelines to form a closed system. When the system operates, the compressor draws the low-temperature, low-pressure refrigerant vapor generated by the evaporator into the cylinder. After being compressed by the compressor, the pressure increases (and temperature also rises) to slightly above the pressure inside the condenser, at which point the high-pressure refrigerant vapor in its cylinder is discharged into the condenser. (Therefore, the compressor acts to compress and transport the refrigerant.) In the condenser, the high-temperature, high-pressure refrigerant vapor exchanges heat with cooler air (or normal temperature water) and condenses into liquid refrigerant. This liquid refrigerant then enters the evaporator after being cooled (and depressurized) by the expansion valve, where it absorbs heat from the cooled object and then vaporizes. In this way, the cooled object is cooled, and the refrigerant vapor is drawn away by the compressor. Thus, a cycle is completed in the refrigeration system through four processes: compression, condensation, expansion, and evaporation.

The principle of the refrigeration system is shown in the figure below:

2. Temperature Control System

The core component of the temperature control system is the temperature sensor. The temperature sensor automatically samples and instantly monitors the ambient temperature. When the ambient temperature is higher than the control setpoint, the control circuit starts, and a control hysteresis can be set. If the temperature continues to rise, when it reaches the set over-limit alarm temperature point, the over-limit alarm function is activated. If the controlled temperature cannot be effectively controlled, the equipment can also be stopped from continuing to operate through a tripping function to prevent damage.

The temperature control system is an important hardware component in a chromatography cabinet. Key factors to consider are the sensitivity, number, and distribution of sensors, as well as temperature control performance. Generally, parameters such as temperature control range and accuracy are determined by the temperature controller and are not closely related to the chromatography cabinet itself. Some temperature control systems can control a wide range of temperatures, but actual temperature control needs to be determined by the chromatography cabinet's own refrigeration system; temperature control uniformity also requires integration with the chromatography cabinet for good results.

3. Air Duct Design

The internal air duct design of a chromatography cabinet is the part most easily overlooked by manufacturers, yet the reasonableness of the air duct design directly affects the temperature stability and uniformity of the chromatography cabinet, and thus the overall usage effect. The internal design of the chromatography cabinet should consider the difference in density between cold and hot air, apply active air supply from fans to form an active and uniform airflow throughout the cabinet; factors such as whether short-circuit air circulation will occur, minimizing the impact on cabinet airflow when opening the door, and the design of the fan's air supply capacity also need to be considered.

Internal Airflow Diagram of Chromatography Cabinet

4. Chromatography Cabinet Accessories

Multi-functional chromatography cabinets can generally accommodate the needs of drug storage while meeting chromatography experimental requirements, thereby improving the utilization efficiency of the chromatography cabinet. Therefore, it should first be equipped with columns and clamps for fixing chromatography columns, followed by shelves for placing instruments and equipment (with a certain load-bearing capacity), and additionally, internal power supply, which should generally be waterproof and leak-proof sockets. For drug storage, a corresponding number of storage racks should be configured, and they should be interchangeable with the shelves used for chromatography. The columns and clamps used for chromatography should be removable or not interfere with the placement of drug storage racks.

IV. Key Performance Indicators of Chromatography Cabinets

Ultimately, a chromatography cabinet is a low-temperature cabinet, and its core function is to provide a low-temperature environment. Therefore, temperature performance indicators are the most important, such as: temperature uniformity, temperature stability, and temperature control accuracy. Of course, temperature performance indicators are the ultimate manifestation, and their quality is guaranteed by hardware performance and design, such as: compressor performance, fan performance, overall refrigeration system design, cabinet thickness, foaming quality, internal cabinet design, air duct design, and so on.

In summary, several performance indicators, including compressor performance, internal air duct design, and temperature uniformity, should be strongly focused on. The quality of the compressor ensures the performance and stability of the refrigeration system; the internal air duct design ensures a reasonable cold airflow inside the cabinet, allowing the temperature control system to achieve the best control effect; and temperature uniformity is an overall reflection of the cabinet's comprehensive performance.